"There is a rapidly closing window of opportunity to secure a liveable and sustainable future for all."

We are currently creating more waste every year, which is likely to bring down the quality of our life in the years to come. And we have less than 10 years to halve greenhouse gas emissions until 2050 to reach net zero.

The development conundrum

India submitted its Long-Term Low Carbon Development Strategy in November 2022 with a long-term goal of achieving net zero by 2070, while reducing its emission intensity of GDP by 45% below 2005 levels by 2030.

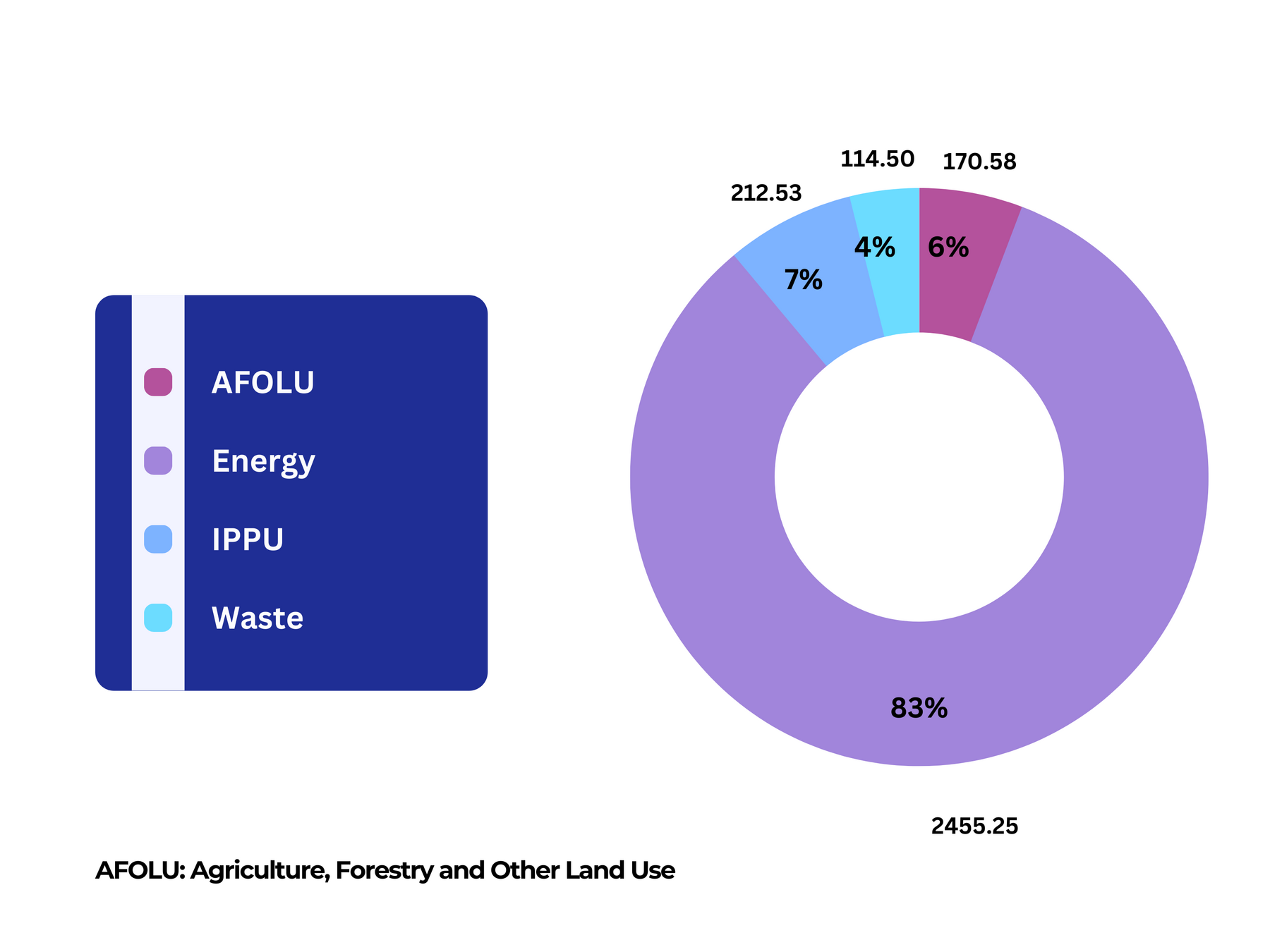

Breaking down the India GHG emissions by sector (in Million Tonnes of Carbon Dioxide Equivalent),

Here’s a statistic to put things in context. As per a joint study by the Niti-Aayog and the Centre for Science and Environment, in 2021, the per capita per day solid waste generation across 28 selected cities of India fell under the range of 190 to 990 gm, the average being 390 gm.

This brings us to a pertinent subject that is often overlooked in the venture space – Circular Economy. India generates 1,60,000 tons per day of waste out of which only 30% is treated, and 30% of this is unaccounted for. At face value, the broad emissions due to “waste disposal” is only 0.5% of India’s total GHG emissions in 2018.

But what about emissions generated by the extraction and generation of virgin materials produced to support the demands of a fast-growing nation? Of course, we can’t exclude a conversation on fast-depleting resources and the ecological debt created by these consumption levels.

Let us take a step back and zoom in on circularity.

Infinite resources?

A linear economy or a cradle-to-grave model, while providing modern convenience, assumes we have infinite resources.

The Earth Overshoot Day arrives earlier each year, with July 28 being the date in 2022. This means that humanity currently uses 75% more than what the planet's ecosystems can regenerate. Until the rest of the year, we operate on ecological deficit spending.

To put things in perspective, we need ~2 earths right now to support our consumption patterns. At the current resource consumption rate, our oil will be over in ~40 years.

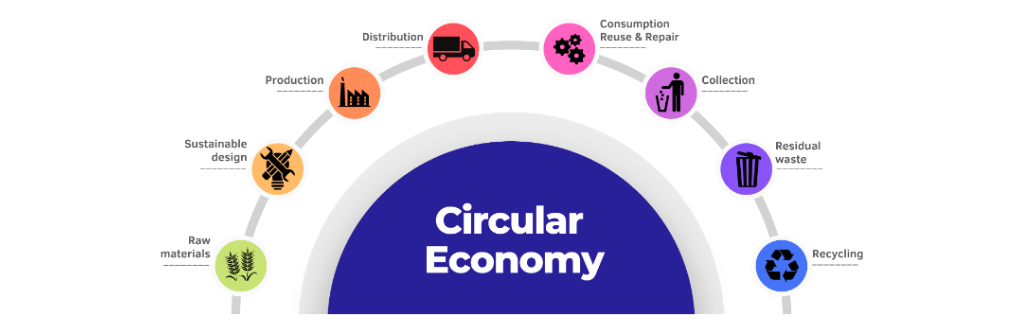

A circular economy is a regenerative system, a cradle-to-cradle model that intends to reuse resources and reduce pressure on primary materials. However, the global economy is only 7.2% circular, which means that more than 90% of materials are either wasted, lost or remain unavailable for reuse for years.

How can this be achieved?

Looking into the white spaces

Environmentalists have called for a complete plastic ban but can we really live without life-saving medical devices? The answer is NO. Instead, the economy must be redesigned for better reuse, repurposing, refurbishment and product life extension, and of course, managing it. A circular economy has immense potential for entrepreneurs to innovate and unlock value across industries.

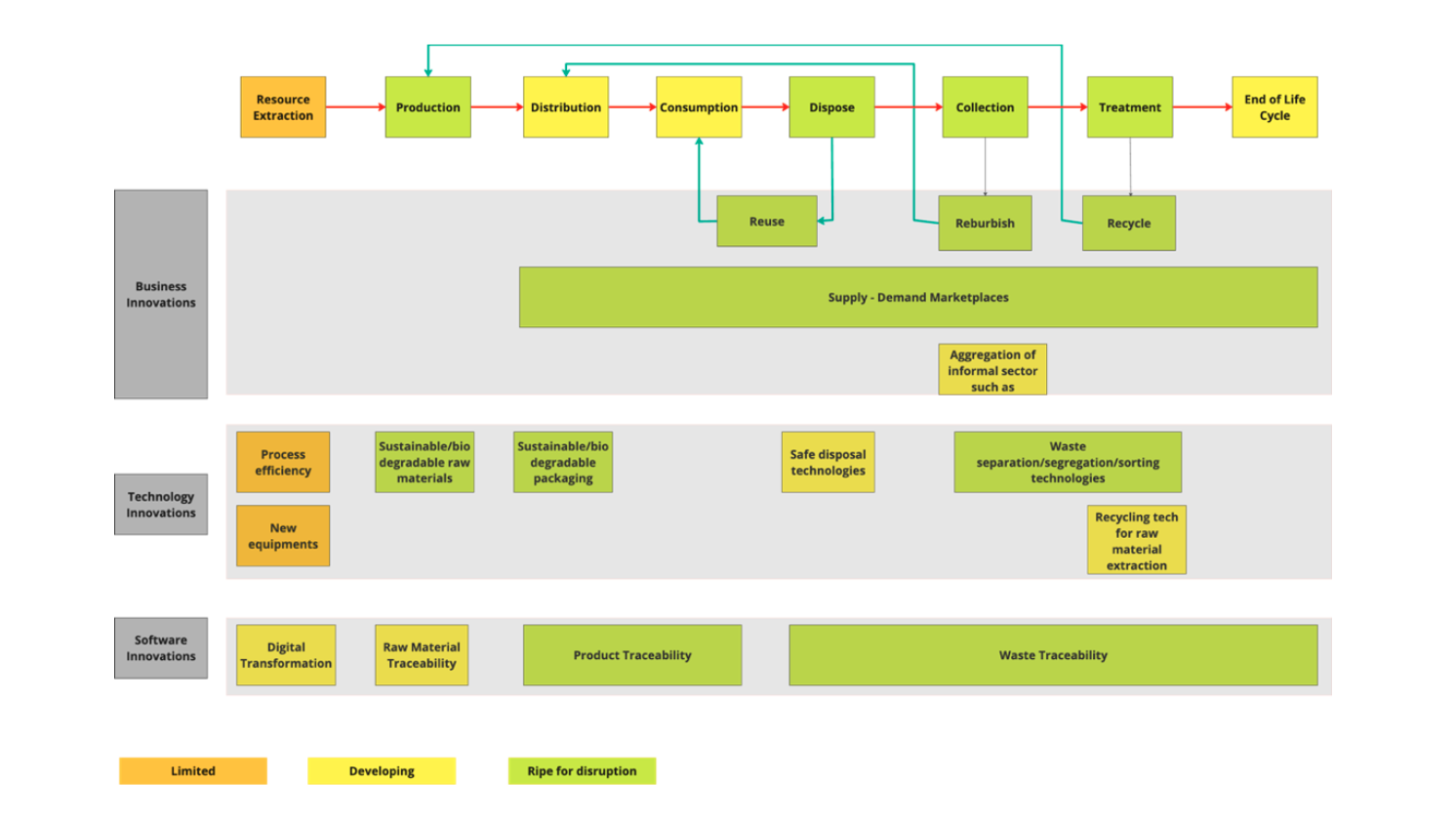

There are multiple ways to look at the circular economy sector. Below is an attempt from our end to identify the potential business, technology and software solutions that can disrupt various nodes in the circular value chain (i.e cradle to cradle).

1. Sustainable Raw Materials

- One of the most abundant inputs in production is fossil fuels for energy. Utilizing renewable biomass resources, such as agricultural waste, algae, and forestry by-products, to produce bio-based materials can reduce reliance on fossil fuels and non-renewable resources. This includes the production of biofuels, bioplastics, and bio-composites. These materials can utilize the existing waste and turn them into materials of use. From PLA to mycelium, agri-waste to algae, startups can innovate at a breakneck speed to make sustainable materials, be it for packaging or medical-grade plastic.

- Today, Relove is a fashion tech platform enabling resale for brands and sellers, acquiring new customers while reducing carbon footprint.

2. Informal sector integration

Nearly 78% of the e-waste generated in India in 2019-20 remained uncollected. It is significant to note that the informal underground sector (i.e. the local ragpickers, waste collectors) dictates the country’s recycling economy, who work at minimal wages and under hazardous conditions. With the implementation of EPR policies, it is of utmost need for them to be integrated into a workforce. Access to end consumers also brings up an opportunity to implement sorting and segregating solutions at a smaller scale. These fragmented collection centers, if coupled and technologically powered with the right incentives, can bring a disruption in the collection node.

3. Marketplaces

The entire value from resource extraction to end of life cycle dispose suffers from fragmentation, inefficiencies and a lack of trust. At every node are various personas adding value to the chain of events. But if the goods and services have to follow the current chain, it’d continue to be slow, ineffective and operating in silos.

Marketplaces enabling the aggregation of supply and demand truly enable reuse, refurbishment and recycling to ensure smooth flow of products and transactions. In the traditional marketplace: cheaper goods, software modules, logistics service and fintech offerings were the building blocks. In the circular economy marketplace we envision use of technology such as sorting/segregation solutions, provision of traceability, aggregation of complex nodes (such as collection) and enabling earning of plastic credits to be the major wedges on which these businesses can be built.

4. Ensuring traceability

To address challenges like misdeclaration of datasets by producers, on-paper collection for EPR certificates, leakage from authorized recyclers to the informal sector and more, there is a need for a traceable, digitized and accountable system to ensure a robust supply chain. Waste and product traceability are the most ripe for disruption and start from the point of distribution. Implementation of this solution will also be top down (mostly from producers or waste management companies).

5. Innovation in segregation

A large problem that exists today is that of segregation at source. With the government laying guidelines on the segregation and disposal of dry and wet waste, business model innovations like separate material collection systems or tech innovations enabling/incentivizing could steer tectonic changes in the space. Implementation of these solutions can be across the multiple nodes of waste generation and across various scales. The ability to truly build an accurate solution also reduces manpower dependency and can allow other businesses to scale up efficiently.

6. Deep tech solutions

Deep tech solutions have the potential to create significant impact across industries. While we have covered some of them above, here is a summary of it all:

- Robotics and automation technologies can optimize manufacturing processes, improve resource efficiency, and enable the safe and efficient disassembly of products for recycling or remanufacturing. They can also enhance sorting and separation processes in waste management systems.

- Blockchain technology can enhance transparency, traceability, and trust in supply chains. It enables secure and immutable recording of transactions, facilitating the tracking of materials, verifying certifications (e.g., sustainable sourcing), and enabling efficient sharing of information among stakeholders.

- Deep tech solutions like chemical recycling, plasma gasification, and pyrolysis can enable the efficient recycling of complex materials that are traditionally difficult to recycle, such as mixed plastics, electronic waste, and composite materials. These technologies can convert waste into valuable raw materials, enabling a closed-loop system.

- Advanced Materials: Developing and utilizing advanced materials with unique properties can enable more sustainable and durable products.

- Nanotechnology can contribute to sustainable materials development, including enhanced durability, improved energy efficiency, and reduced resource consumption. It enables innovations in areas such as nanocomposites, nanocoatings, and nano-enabled sensors for improved product performance and circularity.

- Biotechnological solutions, such as bio-based materials, biofuels, and biodegradable alternatives, can replace fossil-based products and reduce environmental impact. Biotechnology can also play a role in waste treatment and valorization, such as through bioconversion and bioremediation processes.

Technology and marketplaces enabling closed-loop recycling will incentivize the entire waste value chain and build moats in businesses.

7. Electronics Recycling/Refurbishing

While there is an increased demand for electronics and rare earth materials in batteries, recycling rates are pretty low due to affordable & scalable tech limitations and supply of materials.

In the space of electronics, business model innovations leveraging principles of reuse or refurbish are being solved for. A key challenge for electronics is a lack of standardization amongst producers citing competition and IP. Models such as remanufacturing or product as a service can help in mainstreaming the circular economy by working with manufacturers at the source.

Our portfolio company Cashify, while creating a marketplace for refurbished gadgets, incentivizes e-waste collection and has accelerated a transition to a circular economy. It’s interesting how its founders, Mandeep Manocha and Nakul Kumar meandered through scrapyards to build a solution that helps phones get a second life. We have covered their story in detail here.

The above whitespaces identified are by no means exhaustive! We would love to hear from anyone who is building in this space. We promise a response from our end! Please write to climate@blume.vc.

Sources:

- https://report.ipcc.ch/ar6syr/pdf/IPCC_AR6_SYR_LongerReport.pdf

- https://unfccc.int/sites/default/files/resource/India_LTLEDS.pdf

- https://www.ghgplatform-india.org/

- https://www.circularity-gap.world/2023

- https://cpcb.nic.in/uploads/MSW/MSW_AnnualReport_2020-21.pdf

- https://citizenmatters.in/wp-content/uploads/sites/14/2018/07/Saahas-Zero-Waste-Profile_2018.pdf

- https://cpcb.nic.in/e‑waste/

- https://reports.fashionforgood.com/wp-content/uploads/2022/07/Sorting-for-Circularity-Wealth-in-Waste.pdf