Fuel for future: which minerals define the growth of electric mobility?

- Published

- Reading Time

- 2 minutes

We’re past the stage where we are discussing if EVs are indeed the future of mobility. A more intriguing question for the current times would be: which element/mineral defines the future?

Roughly 50% of the cost of an EV is the cost of its battery and ~35% of the price of that battery is actually the cost of its raw materials. The type and procurement of raw materials will catalyse the next wave of innovation and disruption.

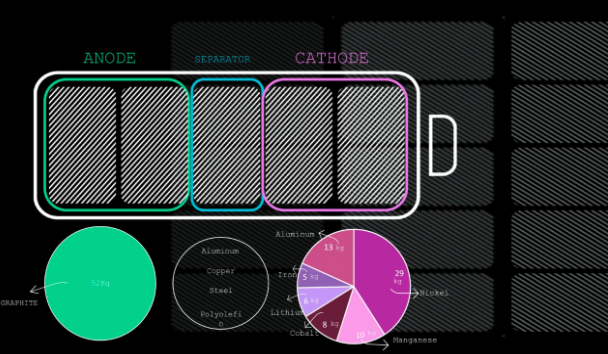

Below is a basic breakup of the battery's three parts

- Cathode

- Anode

- Separator, cell casings etc.

Each one of them is made up of some element.

An average battery would use ~185-189kgs of these raw materials.

A cursory glance suggests that the cathode is the most expensive component of the battery due to the sheer range of materials required to build it.

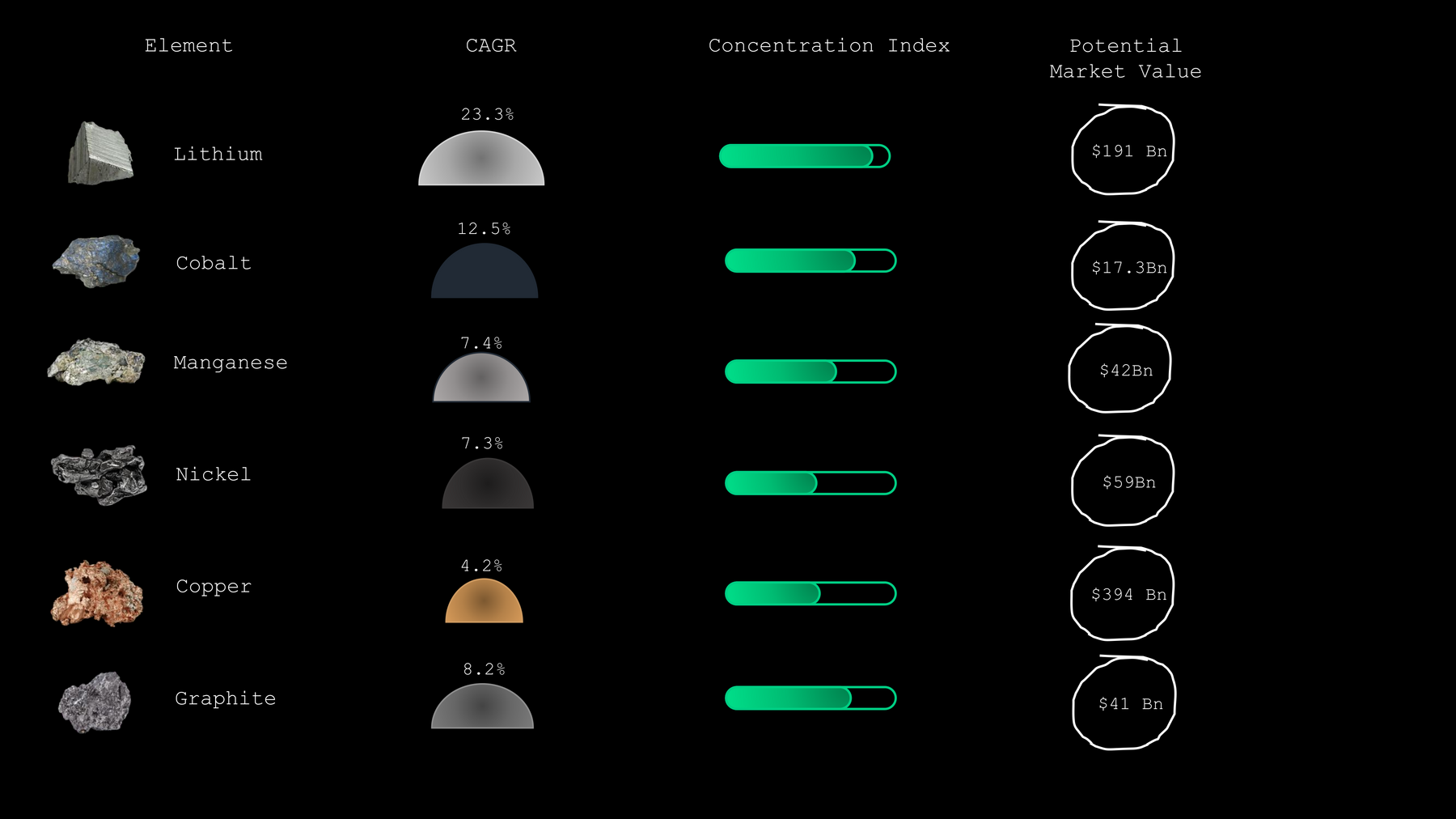

In the above graphic,

- Concentration Index is the degree of geographical concentration of that element. For example, 2/3rd of natural graphite is mined in China.

- Potential Market value by 2030- based on demand and supply estimates and considering EV as the significant use case.

- Lithium, Cobalt and Graphite have the highest CAGR amongst other elements due to paucity of supply, high concentration in a few regions and mining restraints.

There are a few observations that we can make from this:

- Can the use of these metals actually pose a geopolitical risk for nations? If yes, to what extent? For example, China would continue to dominate the global production of Li-ion batteries due to its control over the key elements (such as graphite) of cathode and anode.

- If the answer is yes, recycling material as a business is expected to become big and central to the value chain. To make batteries greener and more affordable, recycling is the accelerator that India needs to push through the EV transition

- Material innovation is the need of the hour. These would include compact batteries, higher energy density, and material replacement for cobalt (at current utilization rates, we are expected to run out of cobalt by 2030). Hydrogen, sodium, etc are the top contenders but the timeline involved in the research, pre-beta/beta roll-out to commercialization of these materials might get stretched. Thus, Lithium will continue to exert dominance at least in the foreseeable future.

- Is the battery really that green? One tonne of Lithium requires ~500,000 gallons of water. Interestingly, Bolivia, the largest Li-producing region, is also one of the world's driest regions. From extraction of materials to production to disposal, when the entire lifecycle of an EV is concerned, the end outcome might not be a shade that is as green as we expected.

While we don’t have answers to everything yet, solving these questions would determine the direction of EV growth in the next decade.